FAN CLUTCHES

Why GMB Fan Clutches?

Not all fan clutches are the same. Here’s what makes our fan clutches stand out.

High-Quality Carbon Steel Flange (Ball Bearing)

GMB uses high-quality carbon steel that is made to withstand high impacts, have high billet density, and have high deformation resistance. Every GMB Ball Bearing is machine press-fitted to the main case using the proper force range.

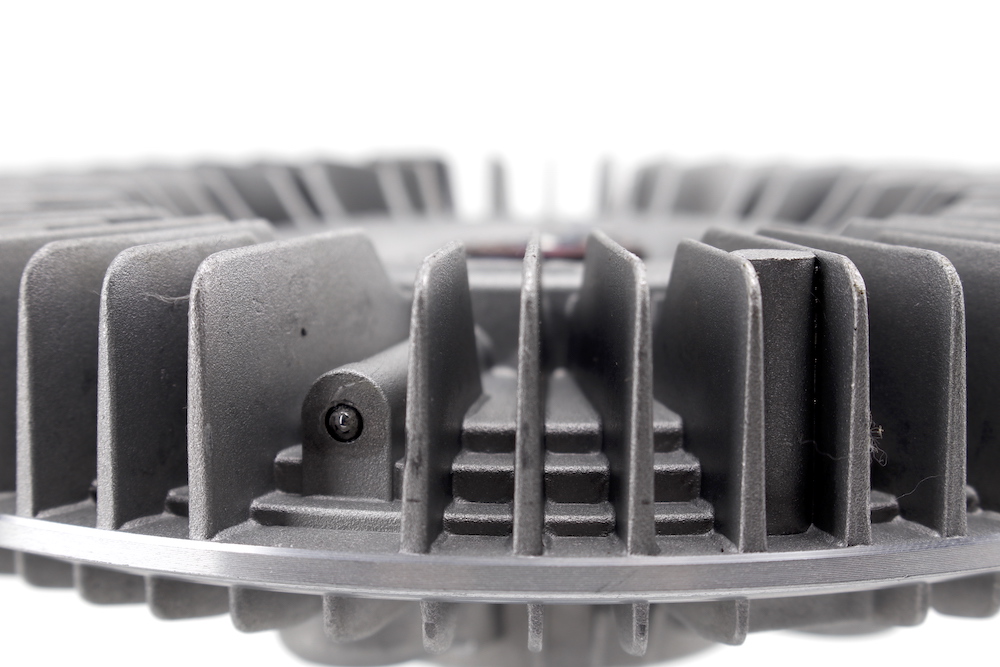

Precision OEM-Spec Fan Clutch Components

GMB Fan Clutch components are manufactured to match the exact OEM spec materials: high-quality cold rolled steel, aluminum, and carbon steel. Each component is precision measured using state-of-the-art technology to be dimensionally correct, with 99.99% accuracy and strict tolerance limits.

Precision OEM-Spec Test Standard

GMB Fan Clutches are manufactured to match the exact OEM performance that’s intended for the vehicle. Each fan clutch is also precision tested using rigorous standards to maintain 99.99% accuracy and strict tolerances.

Proprietary OE Fixed Design

GMB has supplied and worked with OEMs for years and knows most fan clutch issues relate to noise or oil leakage. To prevent oil leakage, GMB Fan Clutches include an oil seal on top of the rotor. GMB also revised the design of the oil seal from a single oil seal to a double oil seal and expanded the return hole to retrieve all oil from the rotor.

We're Continiously Developing New Products

We research, manufacture, and release hundreds of new products every year to make sure we have the parts you need.

Latest Fan Clutch News

How To Maximize The Performance And Lifespan Of Your Fan Clutch

Preventative maintenance is the key to maximizing the performance and durability of any fan clutch. Here’s a list of maintenance tips to share with your customers:

- Ensure the thread surfaces of the Fan Clutch and Water Pump are clear of any debris.

- Screw the Fan Clutch onto the Water Pump threads ensuring the threads interlock properly.

- Torque the Fan Clutch to the correct specification, following the manufacturer’s recommendation.

- Use tools specifically designed for the Fan Clutch to ensure the pulley does not move while turning the threaded nuts.